Tough moulded plastics for medical sector

Tough moulded plastics for use by medical & healthcare sectors worldwide

Medical

UK & international

With over 80 years’ experience in the manufacture of electrical equipment, our client specialises in the research, design and development of equipment for the medical and healthcare sectors, establishing an excellent reputation for reliable, accurate and user-friendly engineering that saves lives worldwide.

Medical suction equipment and pipeline regulators, together with equipment such as battery units, nebulisers and filters, are manufactured by our client in the UK and distributed nationally and internationally for use in hospitals, surgeries, clinics, by paramedics and at-home care. Part of a suite of products transferred to OF Bell by our client, our team delivers durable moulded plastic parts throughout the year for integration into our client’s pipeline suction and regulator assemblies.

Our client transferred the injection moulding production of its moulded plastic parts to OF Bell following the closure of its previous supplier’s business. Proudly developing its medical sector equipment in the UK, our client approached OF Bell as a UK-based manufacturer for reliability of supply and to benefit from a close working relationship.

Tools which had been used for around 40 years were upgraded and modified to suit OF Bell’s modern, state-of-the-art machinery by our in-house tooling workshop team, bringing old tools back to life and preserving these valuable customer assets.

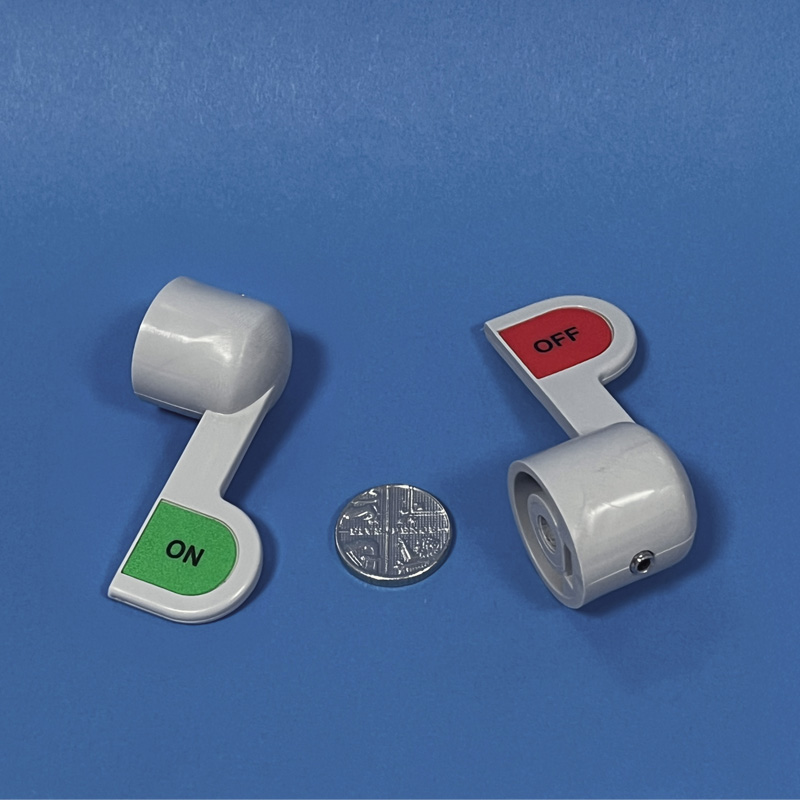

A common sight in healthcare settings, pipeline suction devices manufactured by our client offer fully variable suction levels, with safety features including fitted filters, overflow traps and pressure relief valves. Injection-moulded by OF Bell, an easy-to-view shut off lever allows for fast manual control of the system.

OF Bell specified a grey, medical-grade POM acetal material for this moulded plastic shut off lever, a popular compound that offers excellent rigidity and strength, low friction, good wear and impact resistance properties, and resistance to moisture which is essential in medical suction equipment such as this. For consistency in our client’s finished products, OF Bell colour-matched our master batch to previous batches, ensuring a seamless customer experience for our client’s purchasers.

Using our adapted multi-cavity tooling and a combined shot weight of 25g, OF Bell produces around 1500 shut off lever units annually on our operator-controlled 50T injection moulding machine at our facility in Bishop Auckland, County Durham, protecting our client’s product design and business interests throughout.

Delivered promptly to our client’s own manufacturing facility by our onshore team, production lines run consistently and smoothly, relying on a regular supply of shut off lever moulded plastic parts that are quality-assured and ready to be integrated into assemblies straight away.

Adding considerable value to our client’s production processes, OF Bell delivers fully-assembled, moulded plastic shut off lever parts which help our client to reduce its manufacturing times for each piece of equipment.

Each unit is assembled by OF Bell, inserting a small screw and nut, and adding on/off labels to the lever handle. Benefiting from low minimum order quantities, a ready-assembled “out of the box” single component, and reliable supply from a UK-based manufacturer, our client’s production lines deliver essential medical devices to healthcare service providers worldwide on time, and on budget.