Complex miniature plastics for textile manufacturing equipment

Complex miniature moulded plastic components for sensor technologies in the textiles sector

Textiles

UK & international

Founded at the height of the Industrial Revolution in Europe, our client is now a global leader in the design and development of technologies for use in the textiles industry, particularly machinery, components and automation for the production and inspection of yarn for carpets, staple fibre, tyre cord and industrial yarns.

Technologies and machinery produced by our client are used internationally to process yarns and fibres, helping organisations to create a diverse range of products backed by excellent industry and process understanding and cutting-edge research and development. Fed into our client’s production lines are some of the smallest moulded plastic components manufactured by OF Bell, delivered on schedule to support efficient textiles production worldwide.

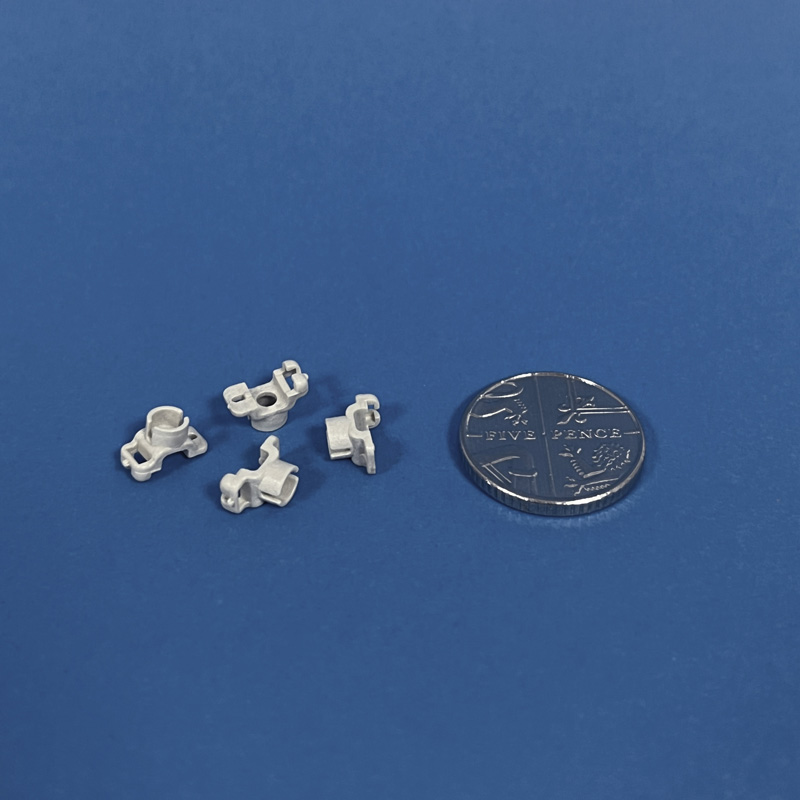

Working closely alongside our textiles sector manufacturing client, OF Bell’s complex miniature moulded plastics specialists assisted with the development of this 8mm-wide miniature moulded plastic component for use in carpet weaving and other textile processing sensor technologies.

Each component is used as a magnet mount, integrated into laser vision sensor equipment to hold magnets in place during the manufacturing process as part of a much larger assembly.

Accurate sensor technologies are essential in the manufacturing of textiles such as carpets, maintaining product consistency and quality in order to meet customer demand and expectations. OF Bell has supported the textiles sector for many years, delivering miniature components including complex moulded plastics and complete electronic sensor assemblies for use in equipment and machinery that ensures reliability and continuity.

As part of our Product Design & Development phase, OF Bell designed a new multi-cavity tool that delivered maximum production from every shot, maintaining the quality and strength of plastics despite the miniature scale of these moulded plastic components.

Manufactured entirely in-house by OF Bell at our tooling design and injection moulding facility in Bishop Auckland, County Durham, complex miniature moulded plastics for our textiles equipment client are produced using a liquid crystal polymer (“LCP”). This advanced engineering polymer is strong and holds stiffness well, making these miniature moulded plastics durable and robust to withstand use in heavy machinery.

Complex plastic parts are moulded by OF Bell using shot weights of 3.02g on our 6T vertical injection machines, which are ideal for the accurate and consistent production of small parts. Quality inspections are carried out throughout production at regular intervals, ensuring value for our client from every shot whilst minimising wastage.

OF Bell injection moulds around 200,000 miniature plastic magnet mounts for our client annually, producing around 25,000 units in each batch. 24/7 manufacturing capability by our team, expert tooling design in-house, and dedicated complex miniature plastics technologies have enabled our client to scale up production as demand for its products continues to grow globally.

Delivering unmatched quality assurance and consistency, our miniature moulded plastic parts are dispatched promptly by our UK-based team, avoiding expensive shipping costs and problematic delays to keep our client’s production lines fully operational.